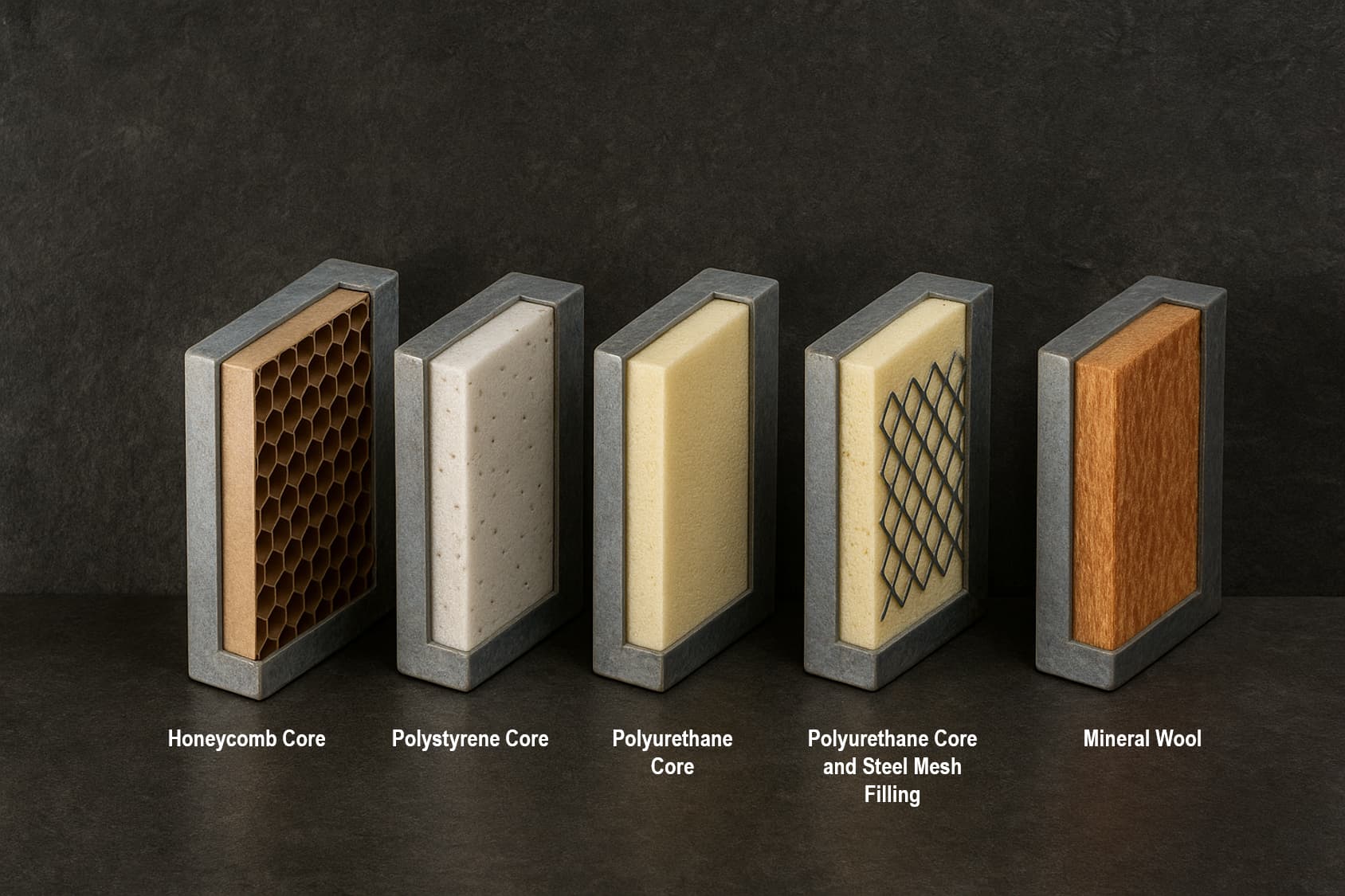

When it comes to steel doors, what’s on the inside matters just as much as the sturdy exterior. The core material of a steel door is essential to its overall performance, influencing factors such as insulation and sound dampening. In this post, we’ll dive deep into the world of door core materials, helping you understand the options available and how they impact your door’s functionality.

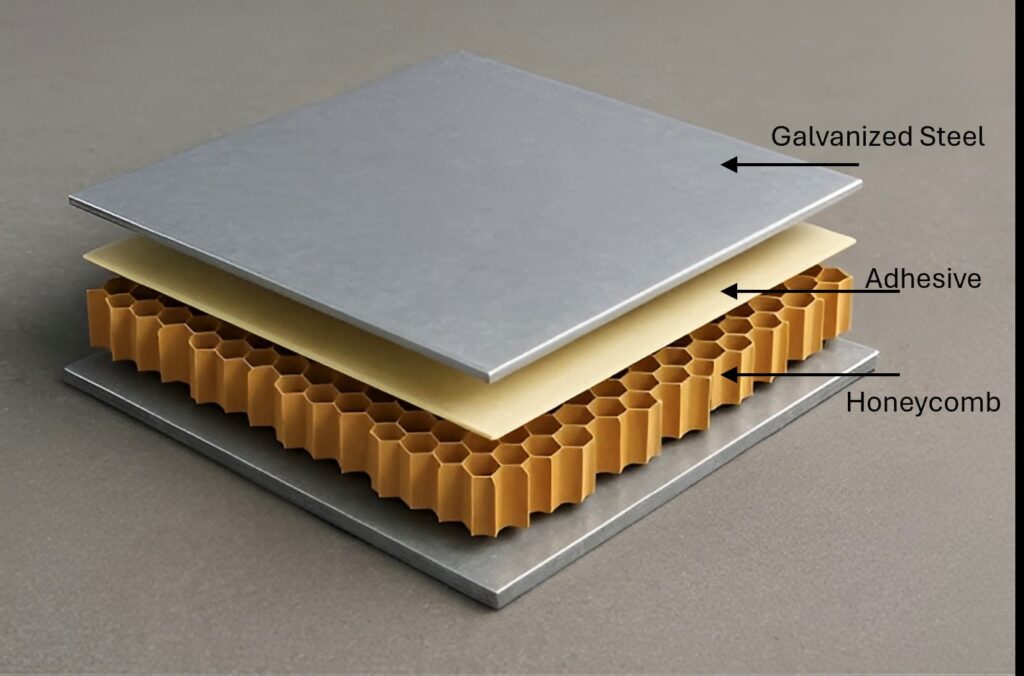

Honeycomb

Consists of a series of hexagonal cells, typically made from kraft paper or aluminum.

- Lightweight yet structurally strong

- Cost-effective option

- Good sound dampening properties

Application

Commercial applications where weight is a concern but insulation is less critical.

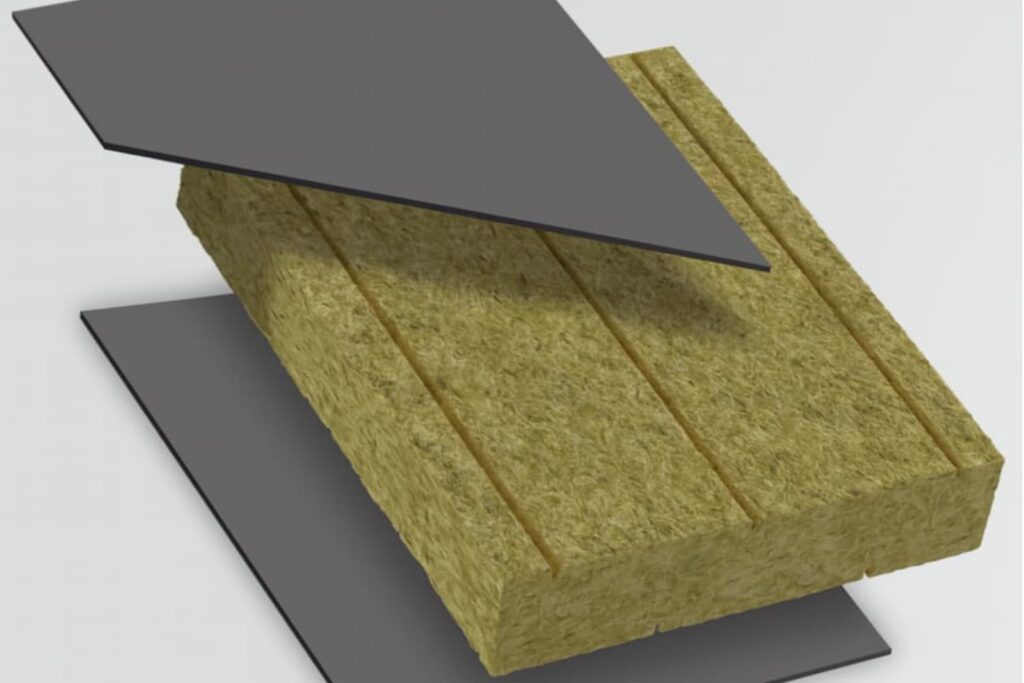

Mineral Wool

A core made from mineral fibers derived from rock or slag.

- Excellent fire resistance

- Good sound insulation properties

- Environmentally friendly and recyclable

Applications

Industrial Setting

Factories and warehouses can benefit from the fire resistance and durability of mineral wool core doors.

Residential High-Rises

Multi-story apartment buildings can use mineral wool core doors to improve fire safety and reduce noise between units

Commercial Buildings

Offices, hotels, and retail spaces benefit from mineral wool’s combination of fire resistance and sound insulation

Healthcare Facilities

Hospitals and clinics can leverage the sound insulation and hygienic properties of mineral wool cores.

Performance Venues

Theaters, concert halls, and recording studios can take advantage of the superior acoustic properties of mineral wool cores.

Polyurethane

A dense foam core created by injecting polyurethane between the door skins

- Superior insulation (highest R-value among common core materials)

- Excellent sound dampening

- Adds significant strength to the door

Applications

Cold Storage Facilities, High-end residential and Commercial Applications;

The superior insulation properties of polyurethane make it ideal for doors in cold storage units, freezers, and refrigerated warehouses

Polystyrene

A solid core made from expanded polystyrene foam

- Excellent insulation properties

- Moisture-resistant

- Adds rigidity to the door

Applications

Residential and light commercial use, especially in areas with temperature extremes.

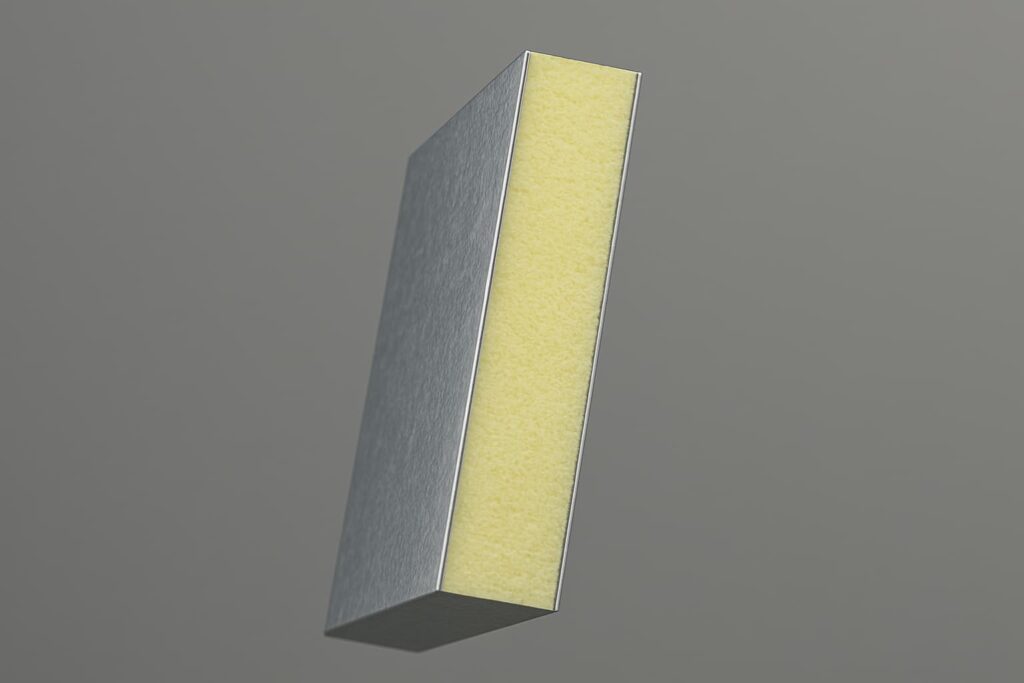

High Density and Polyurethane Foam and Steel Mesh Filling

An advanced version of the standard polyurethane core with increased density.

- Exceptional thermal insulation (even higher R-value than standard polyurethane)

- Superior structural strength

- Enhanced sound dampening properties

Applications

Premium residential and commercial applications demand the highest levels of energy efficiency and performance.

Comparative Analysis

| Material Type | Insulation (R-Value) | Sound Transmission | Structural Integrity |

| Honeycomb | 1.8 | Moderate sound dampening | Creates lightweight doors suitable for high-traffic areas |

| Mineral Wool | 3 to 4 per in of thickness | Excellent acoustic insulation | Adds moderate weight with excellent fire resistance |

| Polyurethane | 5 to 6 | Minimising sound transmission | Provides substantial structural support |

| Polystyrene | 2.5 to 3 | Good sound reduction | Adds moderate weight and rigidity |

| High Density and Polyurethane Foam and Steel Mesh | 7 or higher | Good sound dampening with added structural benefits | Combines lightweight properties with enhanced structural integrity |

By considering these factors alongside your project requirements, budget constraints, and environmental conditions, you can make an informed decision and ensure to meet or even exceed your expectations in terms of functionality, durability, and cost-effectiveness.

Choosing the Right Core for Your Needs

Selecting the appropriate core material for your steel door is a critical decision that can significantly impact the door’s performance, energy efficiency, and overall value. To make the best choice, consider evaluating the specific requirements and prioritise the features that matter most for your application.

Take note of the following important factors before choosing your steel door:

- Climate: In extreme temperatures, opt for High Density Polyurethane or Mineral Wool Cores.

- Budget: Honeycomb cores offer cost-effective solutions for less demanding applications.

- Sound requirements: For quiet environments, consider mineral wool, rockwool, or high-density polyurethane cores.

- Fire safety: Mineral wool and rockwool cores excel in fire-resistant applications.

- Security: PU foam with steel mesh or high-density polyurethane cores provide enhanced structural integrity.

Whether you’re outfitting a commercial space or choosing a door for your home, the right core material ensures your steel door performs optimally for years to come.

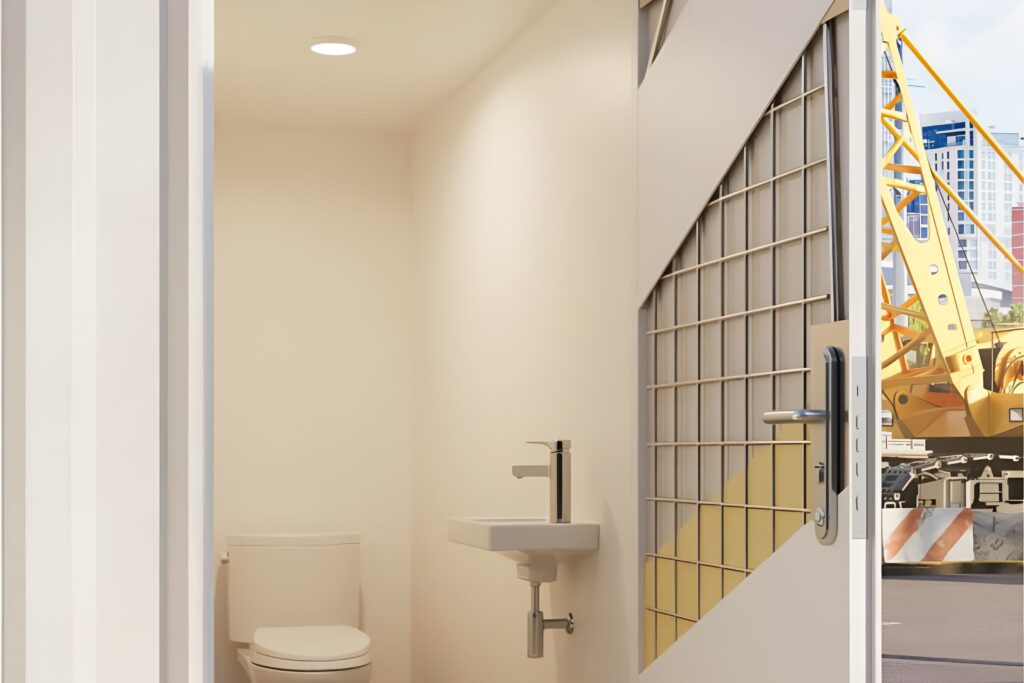

From Strength at the Core to Shipping Container Solutions

At Latham’s, our Shipping Container Doors are built on the strength of a steel core, featuring polyurethane infills with steel mesh for superior durability, insulation, and reliability, perfect for upgrading or modifying containers with robust, insulated performance.